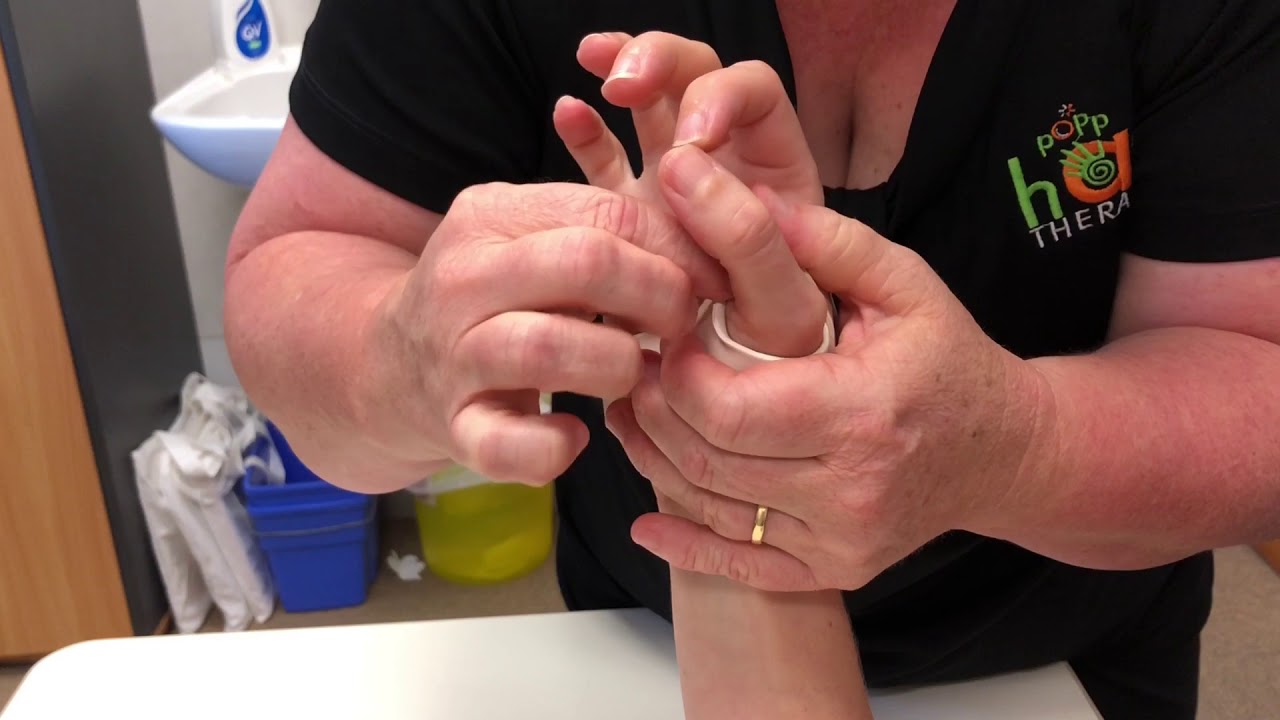

Often referred to as an orthosis, we use the terms splint or brace. The splints we create are custom-made to fit you using thermoplastic material. Splints are adjustable, can be any size, for any joint and are waterproof.

We can make a splint on the spot. It can be adjusted to make sure it fits as often as required. Our creativity is the only thing limiting what we can make to ease your discomfort.